Special Bearing Tech Solutions

Welcome to send us E-mail

Send outScan and communicate with us at any time

To view807064489

Add to

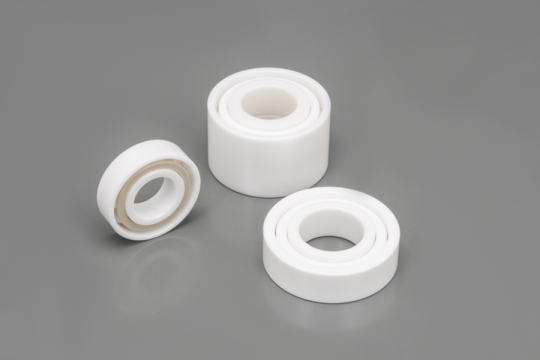

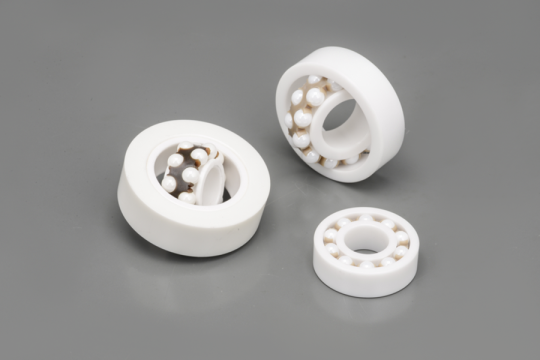

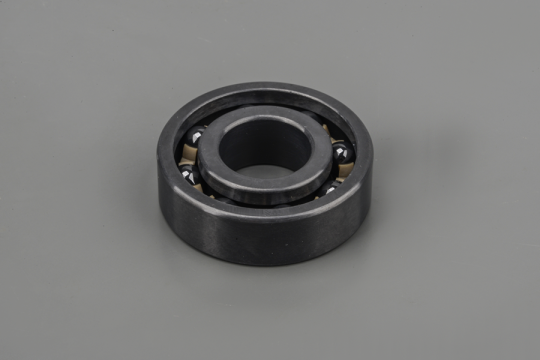

Zirconia (ZrO2) all-ceramic bearing has the characteristics of non-magnetic, electrical insulation, wear resistance, strong acid and alkali corrosion resistance, oil-free self-lubrication, high temperature and high cold resistance, etc., which can be used in extremely bad environment and special working conditions that steel bearings can not adapt to. With stainless steel cage or full ball, can be used in high temperature environment above 450℃. With PTFE or PEEK holder can be used in temperatures above 250℃.

| Ring | Ball | Cage | Usage temperature | Corrosion resistance | Remarks |

|---|---|---|---|---|---|

| ZrO2 | ZrO2/Si3N4/SiC | PTFE | 250℃ | Excellent | According to different use environment, can provide different solutions for customers; Products with a large inventory, welcome your consultation and purchase |

| ZrO2 | ZrO2/Si3N4/SiC | PEEK | 250℃ | Excellent | |

| ZrO2 | ZrO2/Si3N4/SiC | PA66/UPE/PP | 90℃ | Good | |

| ZrO2 | ZrO2/Si3N4/SiC | PET | 110℃ | Good | |

| ZrO2 | ZrO2/Si3N4/SiC | PVDF | 180℃ | Excellent | |

| ZrO2 | ZrO2/Si3N4/SiC | PI | 300℃ | Excellent | |

| ZrO2 | ZrO2/Si3N4/SiC | SUS | 450℃ | Excellent | |

| ZrO2 | ZrO2/Si3N4/SiC | None | 450℃ | Excellent |

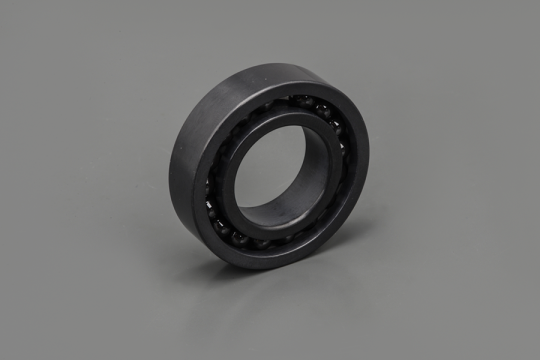

Deep groove ball bearing View size》

Deep groove ball bearing View size》  Angular Contact Bearing View size》

Angular Contact Bearing View size》  Self-aligning Ball Bearing View size》

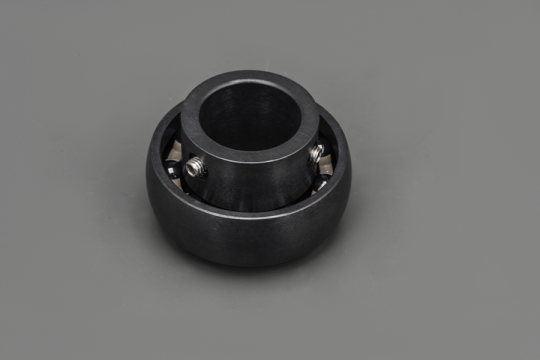

Self-aligning Ball Bearing View size》  Thrust Ball Bearing View size》

Thrust Ball Bearing View size》  Outer Spherical Bearing View size》

Outer Spherical Bearing View size》  Imperial Bearing View size》

Imperial Bearing View size》 | chemical environment | molecular formula | contents% | temperature | Anti-corrosion property |

|---|---|---|---|---|

| Acetic acid | CH3COOH | 80 | boiling | Exellent |

| Acetic acid/Acetic anhydride | CH3COOH+CH3CO | 50/80 | boiling | Exellent |

| Water+Sodium chloride | H2C03 | boiling | Exellent | |

| Carbonate | H2C03 | boiling | Exellent | |

| Copper | Cu | 1400℃ | Exellent | |

| Food acid | boiling | Exellent | ||

| Fruit juice | boiling | Exellent | ||

| Hydrochloric acid | HCL | 35 | 25℃ | Good |

| Hydrochloric acid+Iron oxide | HCI+FaCl2 | boiling | Good | |

| Hydrofluoric acid | HF | 25℃ | None resistant | |

| Nitric acid | HN03 | 83 | 25℃ | Good |

| Nitric acid+Hydrochloric acid | HN03+HCL | 80+20 | boiling | Good |

| Phosphoric acid | H3P04 | 85 | 25℃ | Exellent |

| Potassium hydroxide | KOH | 25℃ | Exellent | |

| Sodium carbonate+Sulfuric acid | Na2C03 4-H2S03 | 18/20 | 925℃ | Exellent |

| Sodium hydroxide | NaOH | 50 | boiling | Exellent |

| Sulfuric acid | H2S04 | 20 | 25℃ | Exellent |

| Sulfuric acid | H2S04 | 98 | 50℃ | Good |

| Aluminum | AL | 100 | 700℃ | Exellent |

| Zinc | Zn | 100 | 5000℃ | Good |

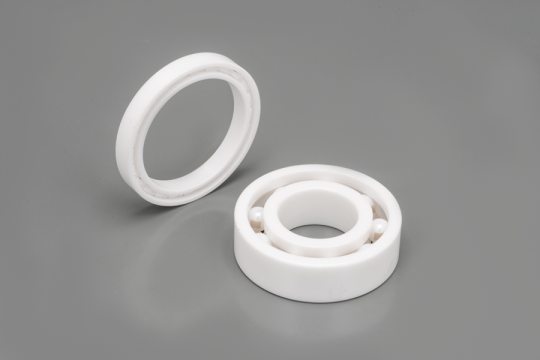

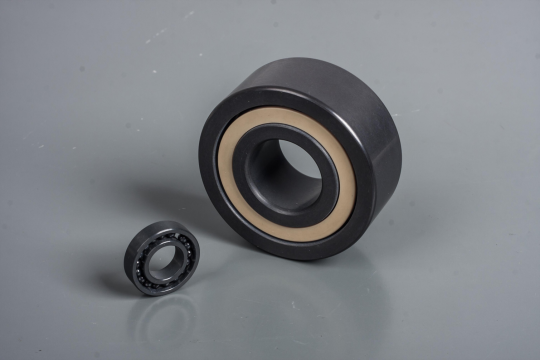

Silicon nitride (Si3N4) all-ceramic bearing has all the characteristics of zirconia ceramic bearing, but also has light weight, high hardness, more wear resistance, more high temperature resistance and so on. It can be used for higher speed and load capacity, stronger acid and alkali chemical corrosion, and worse environment and special working conditions. In the case of full ball, it can be used in high temperature environment above 800℃. With stainless steel cage can be used for 450℃ and above. With PTFE or PEEK holder can be used in temperatures above 250℃.

| Ring | Ball | Cage | Usage temperature | Corrosion resistance | Remarks |

|---|---|---|---|---|---|

| Si3N4 | Si3N4 | PTFE | 250℃ | Excellent | According to different use environment, can provide different solutions for customers; Products with a large inventory, welcome your consultation and purchase |

| Si3N4 | Si3N4 | PEEK | 250℃ | Excellent | |

| Si3N4 | Si3N4 | PA66/UPE/PP | 90℃ | Good | |

| Si3N4 | Si3N4 | PET | 110℃ | Good | |

| Si3N4 | Si3N4 | PVDF | 180℃ | Excellent | |

| Si3N4 | Si3N4 | PI | 300℃ | Excellent | |

| Si3N4 | Si3N4 | SUS | 450℃ | Excellent | |

| Si3N4 | Si3N4 | None | 800℃ | Excellent |

Deep groove ball bearing View size》

Deep groove ball bearing View size》  Angular Contact Bearing View size》

Angular Contact Bearing View size》  Self-aligning Ball Bearing View size》

Self-aligning Ball Bearing View size》  Thrust Ball Bearing View size》

Thrust Ball Bearing View size》  Outer Spherical Bearing View size》

Outer Spherical Bearing View size》  Imperial Bearing View size》

Imperial Bearing View size》 | Technical data | Unit | GCrl5 | 9Crl8 | Si3N4 | ZrO2 |

|---|---|---|---|---|---|

| ρ Density | g/cm³ | 7.8 | 7.9 | 3.2 | 6 |

| α Coefficient of expansion | 10-6/℃ | 11 | 17 | 3.2 | 10.5 |

| IE modulus of elastcity | Gpa | 208 | 200 | 320 | 210 |

| μ Poisson ratio | 0.3 | 0.3 | 0.26 | 0.3 | |

| HV Hardness | Kg/mm | 600 | 700 | 1700~2700 | 1300~1500 |

| Kc Impact strength | W/mk | 20 | 25 | 7 | 11 |

| Compressive strength | Mpa | 2400 | 2600 | 3500 | 2000 |

| λ Thermal conductivity | mm2/m | 30-40 | 15 | 3.5 | 3.5 |

| Ω Specific resistivity | J/KgK | 1 | 0.75 | 1018 | 1015 |

| Specific heat | .℃ | 450 | 450 | 800 | 800 |

| Max temperature | 120 | 150 | 1000 | 800 | |

| Anti—corrossion | None | Weak | Strong | Strong | |

| NO.of stress circle(50%destroy) | 10*106 | 10*106 | 50*106 | 50*106 | |

| Destroy model | Peeling off | Peeling off | Peeling off | Peeling off/Fracture | |

| Anti—magnetism | Have | Have | None | None | |

| Dimension stability | Poor | Have | Good | Good | |

| Insulate properties | No insulation | No insulation | Good | Good |

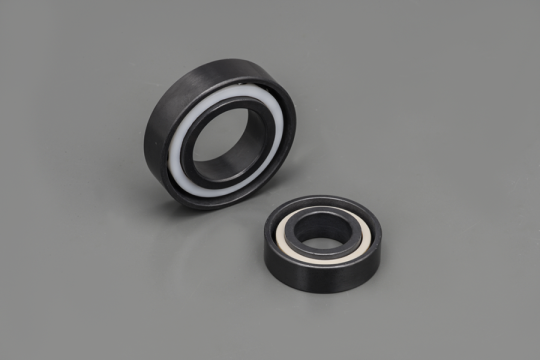

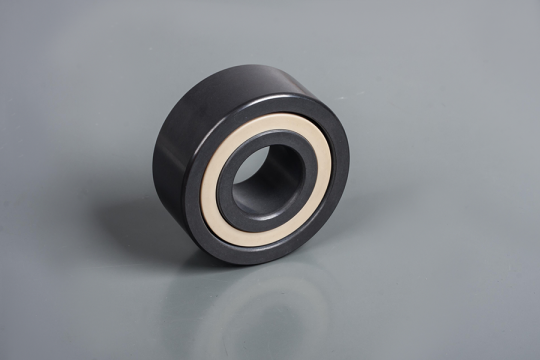

Silicon carbide (SIC) all-ceramic bearings have excellent properties such as high hardness, good wear resistance, high thermal conductivity, low friction coefficient, strong oxidation resistance, good thermal stability and thermal shock resistance. Chemical resistance is the best of the several ceramics, especially hydrofluoric acid (HF) corrosion resistance. Temperature resistance is also the highest in several kinds of ceramics, with full ball, can be used in high temperature environment above 1100℃. With stainless steel cage can be used for 450℃ and above. With PTFE or PEEK holder can be used in temperatures above 250℃.Silicon carbide (SIC) all-ceramic bearings have excellent properties such as high hardness, good wear resistance, high thermal conductivity, low friction coefficient, strong oxidation resistance, good thermal stability and thermal shock resistance. Chemical resistance is the best of the several ceramics, especially hydrofluoric acid (HF) corrosion resistance. Temperature resistance is also the highest in several kinds of ceramics, with full ball, can be used in high temperature environment above 1100℃. With stainless steel cage can be used for 450℃ and above. With PTFE or PEEK holder can be used in temperatures above 250℃.

| Ring | Ball | Cage | Usage temperature | Corrosion resistance | Remarks |

|---|---|---|---|---|---|

| SIC | SIC | PTFE | 250℃ | Excellent | According to different use environment, can provide different solutions for customers; Products with a large inventory, welcome your consultation and purchase |

| SIC | SIC | PEEK | 250℃ | Excellent | |

| SIC | SIC | PA66/UPE/PP | 90℃ | Good | |

| SIC | SIC | PET | 110℃ | Good | |

| SIC | SIC | PVDF | 180℃ | Excellent | |

| SIC | SIC | PI | 300℃ | Excellent | |

| SIC | SIC | SUS | 450℃ | Excellent | |

| SIC | SIC | None | 1100℃ | Excellent |

Deep groove ball bearing View size》

Deep groove ball bearing View size》  Angular Contact Bearing View size》

Angular Contact Bearing View size》  Self-aligning Ball Bearing View size》

Self-aligning Ball Bearing View size》  Thrust Ball Bearing View size》

Thrust Ball Bearing View size》  Outer Spherical Bearing View size》

Outer Spherical Bearing View size》  Imperial Bearing View size》

Imperial Bearing View size》 | Technical data | Unit | 99% Al2O3 | ZrO2 | Si3N4 | SIC |

|---|---|---|---|---|---|

| ρ Density | g/cm³ | 3.7~3.99 | 6 | 3.2 | 3.2 |

| HV Hardness | Kg/mm | 2300~2700 | 1300~1500 | 1700~2700 | 2350~2450 |

| Compressive strength | Mpa | 2800~3500 | 2000 | 3500 | 2250~3000 |

| Fracture toughness | Mpa·m-3/2 | 2~4 | 11 | 7 | 4~5 |

| Weber modulus | Gpa | >7 | >15 | >15 | >6 |

| IE modulus of elastcity | Gpa | 407 | 210 | 320 | 410 |

| μ Poisson ratio | 0.2 | 0.3 | 0.26 | 0.16 | |

| Thermal coefficient | ×10-6/℃ | 6.5~8.6 | 10.5 | 3.2 | 4.3 |

| Thermal shock property | △T℃ | 200 | 250 | 500 | 350 |

| Resistor | Ω/c㎡ | >10~10 | 10~10 | 10~10 | 100~2 |