Special Bearing Tech Solutions

Welcome to send us E-mail

Send outScan and communicate with us at any time

To view807064489

Add to

As the most versatile plastic, POM/PA/PET has good mechanical strength, fatigue resistance and wear resistance. Due to the self-lubrication and low friction coefficient of the material itself, POM/PA/PET is suitable for the production of light weight, low noise, high speed precision plastic rolling bearings. POM bearings are good in alkaline environment, but not suitable for long-term operation in acidic environment, long-term continuous use temperature -50℃ -- 110 ℃; PA bearing is allowed to run in alkali, weak acid and detergent corrosive environment for a long time, long-term continuous use temperature of -40℃ -- 90℃; PET bearings have excellent wear resistance, acid corrosion resistance, radiation resistance, stable to organic solvents and oil, but not heat resistant water immersion, alkali resistance. Long-term continuous use of temperature -20℃ - 115℃.

| Ring | Ball | Cage | Usage temperature | Corrosion resistance | Remarks | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| POM | GLASS/SUS/ZrO2 | PA66 | 90℃ | Good | According to different use environment, we can provide different solutions for customers. |

||||||||

| POM | GLASS/SUS/ZrO2 | POM | 110℃ | Good | |||||||||

| PA | GLASS/SUS/ZrO2 | PA66 | 90℃ | Good | |||||||||

| PET | GLASS/SUS/ZrO2 | PET | 115℃ | Good | |||||||||

| PET | GLASS/SUS/ZrO2 | PA66 | 90℃ | Good | |||||||||

Deep groove ball bearing View size》

Deep groove ball bearing View size》  Angular Contact Bearing View size》

Angular Contact Bearing View size》  Self-aligning Ball Bearing View size》

Self-aligning Ball Bearing View size》  Thrust Ball Bearing View size》

Thrust Ball Bearing View size》  Outer Spherical Bearing View size》

Outer Spherical Bearing View size》  Imperial Bearing View size》

Imperial Bearing View size》

|

Unit | POM | PA66 | MC尼龙 | PET | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Temperature | ℃ | 110 | 90 | 110 | 115 | ||||||||||||

| Density | g/cm³ | 1.42 | 1.14 | 1.15 | 1.36 | ||||||||||||

| Tensile strength | Mpa | 63 | 90 | 85 | 90 | ||||||||||||

| Shaw hardness | HA | 85 | 80 | 85 | 85 | ||||||||||||

| Friction coefficient | 0.35 | 0.25 | 0.36 | 0.25 | |||||||||||||

| Dielectric constant | 1MHz | 3.8 | 3.2 | 3.7 | 3.3 | ||||||||||||

| Volume resistance | Ω·cm | ≥10^14 | ≥10^15 | ≥10^14 | ≥10^15 | ||||||||||||

| Water absorption rate | % | 0.8 | 8.5 | 6.5 | 0.5 | ||||||||||||

| Adhesion | + | + | + | + | |||||||||||||

| Resistant to linear UV | - | - | - | - | |||||||||||||

| Acid resistance | - | - | - | + | |||||||||||||

| Alkali resistance | + | + | + | - | |||||||||||||

| Carbonated water | + | + | + | + | |||||||||||||

| Aromatic substance | + | + | + | + | |||||||||||||

| Ketone resistance | + | + | + | + | |||||||||||||

UPE, HDPE, PP material has good wear resistance and low temperature application characteristics, can be used for relatively weak alkali cross environment, possess general plastic oil-free self-lubricating bearings, magnetic properties, such as electrical insulation resistance, suitable for most alms acid/alkali/salt/solvent/oil/gas and sea water corrosion environment, but this kind of plastic bearings with low mechanical strength, easy to deformation, Not suitable for large load and high speed. Among them, UPE material has the best abrasion resistance and low temperature resistance among known plastics, and its long-term continuous use temperature is -150℃ -- 90℃.

| Ring | Ball | Cage | Usage temperature | Corrosion resistance | Remarks | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| HDPE | GLASS/SUS/ZRO2 | PP | 90℃ | Good | According to different use environment, we can provide different solutions for customers. |

||||||||

| PP | GLASS/SUS/ZRO2 | PP | 100℃ | Good | |||||||||

| UPE | GLASS/SUS/ZRO2 | PP | 90℃ | Good | |||||||||

| UPE | GLASS/SUS/ZRO2 | UPE | 90℃ | Excellent | |||||||||

UPE roller bearings View size》

UPE roller bearings View size》  UPE roller bearings View size》

UPE roller bearings View size》  Anti-static/conductive UPE roller bearings View size》

Anti-static/conductive UPE roller bearings View size》  UPE guide wheel bearing View size》

UPE guide wheel bearing View size》  PE bearing View size》

PE bearing View size》  PP bearing View size》

PP bearing View size》

|

Unit | HDPE | PP | UPE | |||||||||||||

| Temperature | ℃ | 90 | 100 | 90 | |||||||||||||

| Density | g/cm³ | 0.96 | 0.91 | 0.93 | |||||||||||||

| Tensile strength | Mpa | 25 | 30 | 17 | |||||||||||||

| Shaw hardness | HA | 68 | 80 | 65 | |||||||||||||

| Friction coefficient | 0.29 | 0.3 | 0.25 | ||||||||||||||

| Dielectric constant | 1MHz | 2.4 | 2.25 | 3 | |||||||||||||

| Volume resistance | Ω·cm | ≥10^15 | ≥10^14 | 10^2~10^9,10^14 | |||||||||||||

| Water absorption rate | % | 0.03 | 0.01 | 0.01 | |||||||||||||

| Adhesion | + | + | - | ||||||||||||||

| Resistant to linear UV | - | - | - | ||||||||||||||

| Acid resistance | + | + | + | ||||||||||||||

| Alkali resistance | + | + | + | ||||||||||||||

| Carbonated water | + | + | + | ||||||||||||||

| Aromatic substance | + | + | + | ||||||||||||||

| Ketone resistance | + | + | + | ||||||||||||||

PTFE, PVDF and PCTFE materials have good corrosion resistance, high temperature resistance and wear resistance, can be used in all strong acid and strong alkali occasions, including hydrofluoric acid (HF) and fuming nitric acid (more than 98%). PTFE has the best corrosion resistance among all known engineering plastics, and the long-term use temperature can reach 250℃, but THE mechanical strength of PTEF material is very low, and the stability of the size is poor; PVDF and PCTFE materials have high mechanical strength, good size stability, PVDF long-term use temperature can reach 180℃, PCTFE long-term use temperature can reach 170℃.

| Ring | Ball | Cage | Usage temperature | Corrosion resistance | Remarks | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| PTFE | ZrO2/Si3N4/SiC | PTFE | 250℃ | Excellent | According to different use environment, we can provide different solutions for customers. |

||||||||

| PVDF | ZrO2/Si3N4/SiC | PVDF/PTFE | 180℃ | Excellent | |||||||||

| PCTFE | ZrO2/Si3N4/SiC | PCTFE/PVDF/PTFE | 170℃ | Excellent | |||||||||

PTFE bearing View size》

PTFE bearing View size》  PTFE flying saucer bearing View size》

PTFE flying saucer bearing View size》  PTFE roller bearing View size》

PTFE roller bearing View size》  PVDF bearing View size》

PVDF bearing View size》  PVDF roller bearing View size》

PVDF roller bearing View size》  PCTFE bearing View size》

PCTFE bearing View size》

|

Unit | PTFE | PVDF | PCTFE | |||||||||||||

| Usage temperature Temperature | ℃ | 250 | 180 | 170 | |||||||||||||

| Density | g/cm³ | 2.2 | 1.78 | 2.1 | |||||||||||||

| Tensile strength | Mpa | 25 | 50 | 40 | |||||||||||||

| Shaw hardness | HA | 60 | 78 | 80 | |||||||||||||

| Friction coefficient | 0.08 | 0.34 | 0.3 | ||||||||||||||

| Dielectric constant | 1MHz | 2.2 | 7.25 | 2.6 | |||||||||||||

| Volume resistance | Ω·cm | ≥10^18 | ≥10^13 | ≥10^17 | |||||||||||||

| Water absorption rate | % | 0.01 | 0.04 | 0 | |||||||||||||

| Adhesion | + | + | + | ||||||||||||||

| Resistant to linear UV | + | + | + | ||||||||||||||

| Acid resistance | + | + | + | ||||||||||||||

| Alkali resistance | + | + | + | ||||||||||||||

| Carbonated water | + | + | + | ||||||||||||||

| Aromatic substance | + | + | + | ||||||||||||||

| Ketone resistance | + | + | + | ||||||||||||||

PEEK, PI and PPS as emerging engineering plastics materials, in all known engineering plastics have extremely high mechanical strength and dimensional stability, strong corrosion resistance, and the best high temperature resistance, almost can operate in all acid and alkali corrosion environment. The long-term service temperature of PEEK and PPS is 260℃, and the long-term service temperature of PI is up to 300℃.

| Ring | Ball | Cage | Usage temperature | Corrosion resistance | Remarks | ||||||||

| PEEK | ZrO2/Si3N4/SiC/PEEK | PEEK/PTFE | 250℃ | Excellent | According to different use environment, we can provide different solutions for customers. |

||||||||

| PEEK | ZrO2/Si3N4/SiC | UPE/PP | 90℃ | Excellent | |||||||||

| PI | ZrO2/Si3N4/SiC/PI | PI | 300℃ | Excellent | |||||||||

| PPS | ZrO2/Si3N4/Al2O3 | PPS/PEEK/PTFE | 250℃ | Excellent | |||||||||

|

Unit | PEEK | PI | PPS | |||||||||||||

| Temperature | ℃ | 250 | 300 | 250 | |||||||||||||

| Density | g/cm³ | 1.32 | 1.43 | 1.35 | |||||||||||||

| Tensile strength | Mpa | 97 | 116 | 90 | |||||||||||||

| Shaw hardness | HA | 90 | 80 | 88 | |||||||||||||

| Friction coefficient | 0.34 | 0.35 | 0.4 | ||||||||||||||

| Dielectric constant | 1MHz | 3.2 | 3.55 | 3 | |||||||||||||

| Volume resistance | Ω·cm | ≥10^15 | ≥10^14 | ≥10^18 | |||||||||||||

| Water absorption rate | % | 0.2 | 1.3 | 0.02 | |||||||||||||

| Adhesion | + | + | - | ||||||||||||||

| Resistant to linear UV | - | + | + | ||||||||||||||

| Acid resistance | + | + | + | ||||||||||||||

| Alkali resistance | + | + | + | ||||||||||||||

| Carbonated water | + | + | + | ||||||||||||||

| Aromatic substance | + | + | + | ||||||||||||||

| Ketone resistance | + | + | + | ||||||||||||||

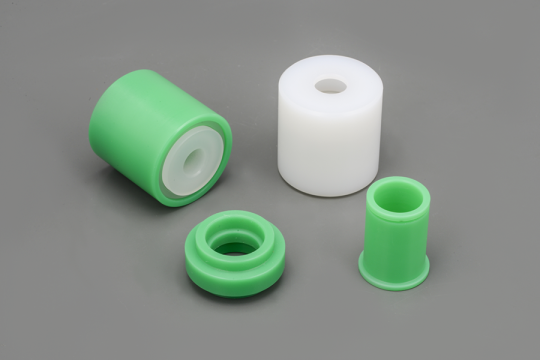

With the increasing complexity of mechanical equipment, standard mechanical equipment bearings have been unable to meet the needs of products, in the face of the different needs of different users, we can provide the products you need for your requirements. If you are interested, please inform us of the product requirements or drawings, we will provide you with special bearings for special occasions.

Swimming pool cleaning bearing

Swimming pool cleaning bearing  Belt pulley bearing

Belt pulley bearing  Plastic coated bearing

Plastic coated bearing  High temperature saucer bearing

High temperature saucer bearing  Universal bearing

Universal bearing  Roller square bore bearing

Roller square bore bearing