Special Bearing Tech Solutions

Welcome to send us E-mail

Send outScan and communicate with us at any time

To view807064489

Add to

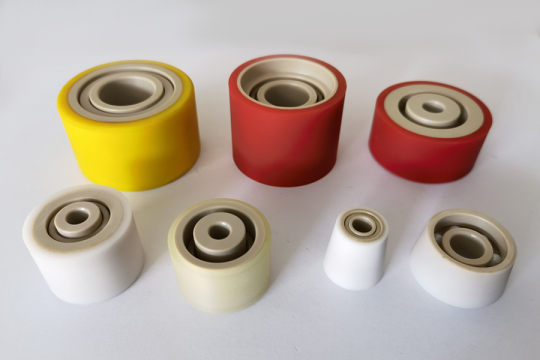

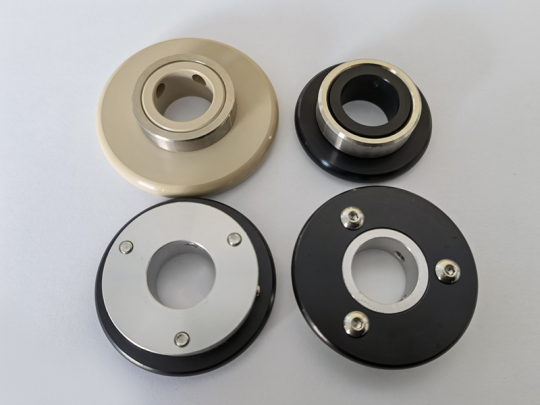

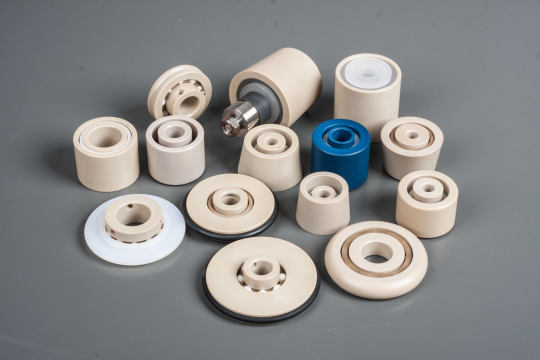

High cleanliness, high precision FPD/TFT-LCD automatic transmission process, cleaning, etching and other liquid crystal spare roller, can be customized according to the user's drawings. In the design and selection, according to the requirements of the specific environment to choose the appropriate material, shape, color and installation method. The roller produced by our company has the characteristics of high precision, good surface roughness and fast delivery time.

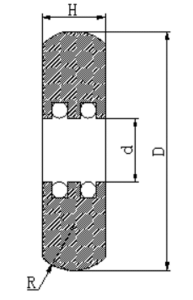

| Roller materials | Fixed way | Surface resistance value | Features |

|---|---|---|---|

| UPE/PEEK/PTFE | POM girdle type | White insulation≥1012Power; Black insulation≥1012Power; Black conductive103~105Power; Black antistatic106~109Power | Low cost,Short delivery time,Easy installation |

| UPE/PEEK/PTFE | Top wire locking type | Low cost,Short delivery time,Easy installation | |

| UPE/PEEK/PTFE | When tight set type | Low cost,Short delivery time,Not easy to tear open outfit | |

| UPE/PEEK/PTFE | Steel ring jacking type | High cost,Short delivery time,Easy installation | |

| UPE/PEEK/PTFE | O-ring stationary | Low cost,Short delivery time,Not easy to tear open outfit |

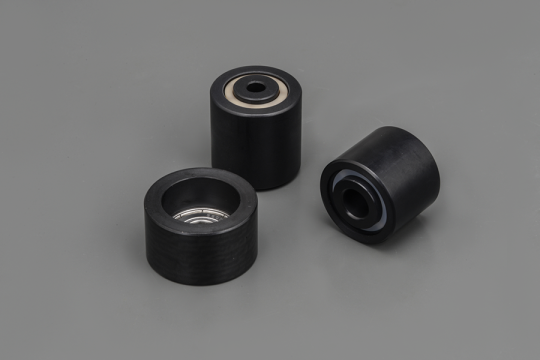

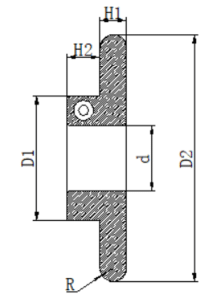

POM ring beam |

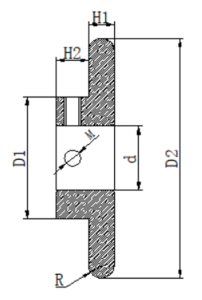

Top wire locking type/steel ring locking type |

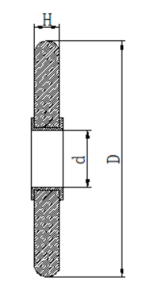

When tight set type |

O-ring stationary |

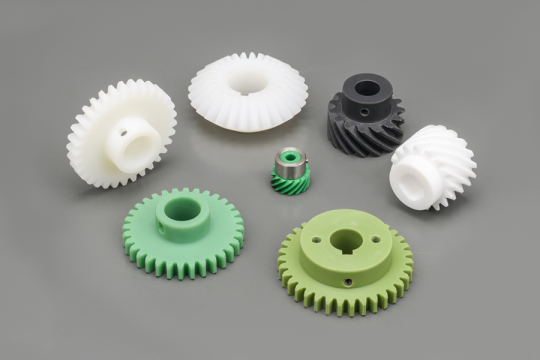

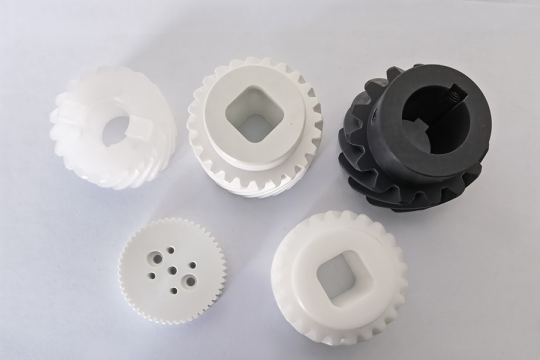

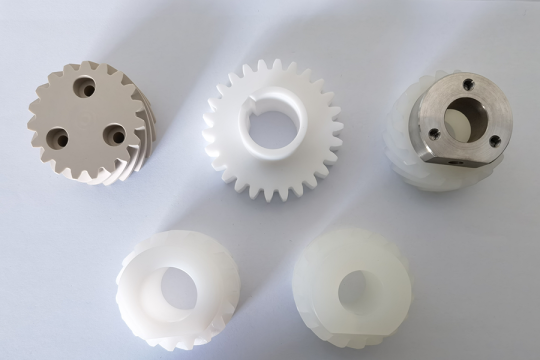

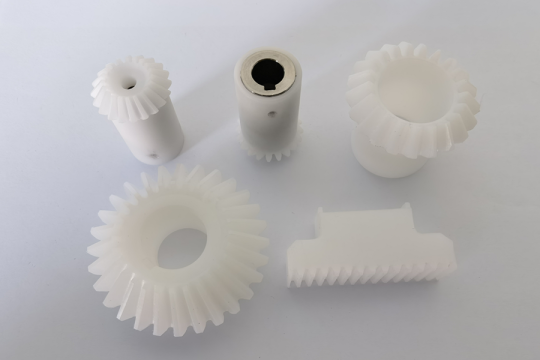

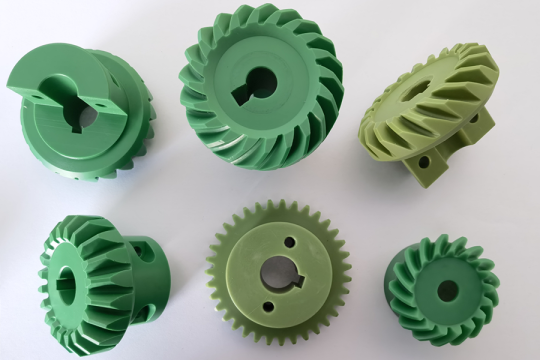

High cleanliness, high precision touch panel production equipment, automatic conveying equipment and TFT/LCD process, touch screen process conveying equipment, cleaning equipment, etching equipment and other transmission gear, can be customized according to user's drawings. In the design and selection, according to the specific environment requirements to choose the appropriate material, shape, etc. Commonly used materials UPE/MC nylon /POM/PTFE/PEEK/PVC/PVDF /PET/PP, the products have the characteristics of wear resistance, corrosion resistance, no magnetic, no dust and so on.

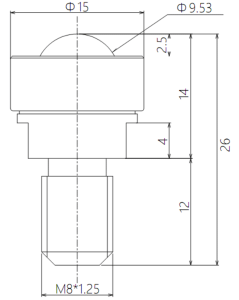

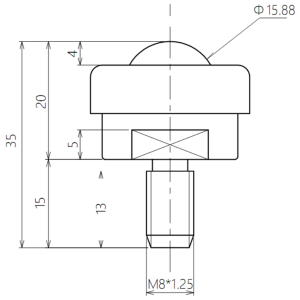

The special universal ball in the clean room is composed of a large ball placed on countless balls, and then matched with the support base, and finally covered with the cover, which can easily make the moving objects move smoothly in 360 degrees. It is widely used in FPD/TFT-LCD manufacturing equipment, semiconductor manufacturing equipment, solar cell manufacturing equipment, etc. It is also suitable for glass positioning under high temperature and vacuum environment.

| Cue ball | Small ball | Ontology | Capping | Remarks |

|---|---|---|---|---|

| PEEK | Stainless steel/ceramic | PEEK | PEEK | According to different use environment, can provide different solutions for customers; Products with a large inventory , welcome your consultation and purchase |

| PEEK | Stainless steel/ceramic | PEEK | PEEK | |

| PI | Stainless steel/ceramic | PEEK | PEEK | |

| PI | Stainless steel/ceramic | PI | PI | |

| POM | Stainless steel | POM | POM | |

| Stainless steel | Stainless steel | POM | POM | |

| Ceramic | Stainless steel/ceramic | Stainless steel | Stainless steel | |

| PEEK | Stainless steel/ceramic | Stainless steel | PEEK | |

| PI | Stainless steel/ceramic | Stainless steel | Stainless steel |

ISC-10 universal ball  ISC-16 universal ball |

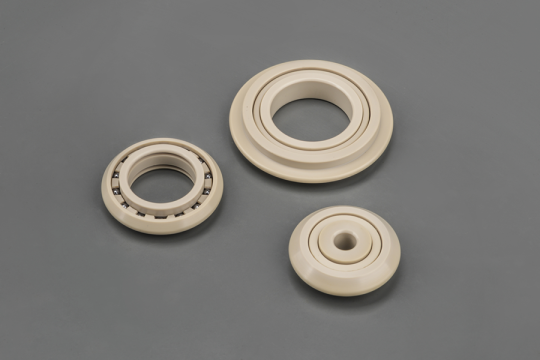

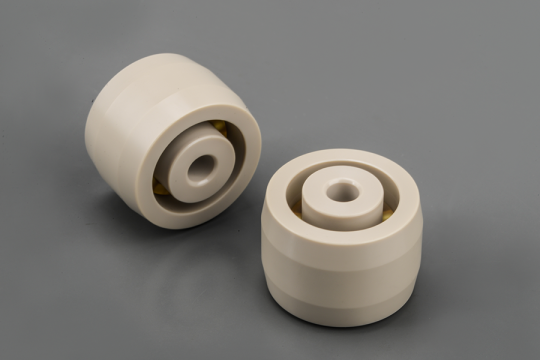

Special guide roller for FPD/TFT-LCD liquid crystal equipment is made of PEEK/PET/UPE/PVDF and other materials, and the rolling body is made of zirconia (ZRO2)/silicon carbide (SIC) and other ceramic materials. Products have wear resistance, high temperature resistance, corrosion resistance and other special points (SIC on HF corrosion resistance is especially good). Widely used in, FPD/TFT-LCD liquid crystal manufacturing equipment for glass transmission, positioning, guidance, etc.

The special rubber guide roller for clean room is covered with a layer of polyurethane PU or fluororubber FKM on the outer diameter of PEEK or PET guide wheel. The product has the characteristics of good elasticity, wear resistance, corrosion resistance, oil resistance and aging resistance, long life and so on.

| Ring | Ball | Cage | Usage temperature | Corrosion resistance | Remarks |

|---|---|---|---|---|---|

| PEEK | ZrO2/Si3N4/SiC/PEEK | PEEK/PTFE | 250℃ | Excellent | According to different use environment, can provide different solutions for customers; Products with a large inventory |

| PEEK | ZrO2/Si3N4/SiC | UPE/PP | 90℃ | Excellent | |

| PI | ZrO2/Si3N4/SiC/PI | PI | 300℃ | Excellent | |

| PPS | ZrO2/Si3N4/Al2O3 | PPS/PEEK/PTFE | 250℃ | Excellent |